It's still a longshot for full-scale production, but a unique research partnership has produced a unique example of biomimicry: a wind turbine that borrows from palm trees to achieve new levels of energy production.

John Kosowatz reports on a breakthrough in the wind turbine technology, advanced through the application of biomimicry. Eric Loth, the chair of mechanical and aerospace engineering at the University of Virginia, has developed a design for a wind turbine inspired by the palm tree. The segmented rotors designed by Loth and his team solve the problem of the massive turbines that would be required to achieve higher levels of energy output than is currently possible with the traditional, three-rotor design of turbines.

The results are potentially game changing—enabling the construction of 50-megawatt turbines. The most advanced turbines are only currently only producing eight to ten megawatts of electricity.

According to Kosowatz, the "design centers on a downwind machine fitted with ultralightweight segmented rotors. During operation and in good weather, they would spread out to catch the wind. During heavy storms or other bad weather, they would fold together like palm fronds and avoid damage."

The design team behind the idea "includes experts in wind turbine design and controls from U.S. universities, the National Renewable Energy Laboratory in Golden, CO, Sandia National Laboratory in Albuquerque," adds Kosowatz.

That multi-disciplinary, public-private partnership is another part of the story that inspired follow-up coverage by Tina Casey for Triple Pundit. Not only does the project represent biomimicry on a massive scale, says Casey, it also shows how "powerful, diversified global corporations are embracing renewable energy," potentially undermining the interests of fossil fuel interests.

FULL STORY: Palm Trees Sway Wind Turbine Design

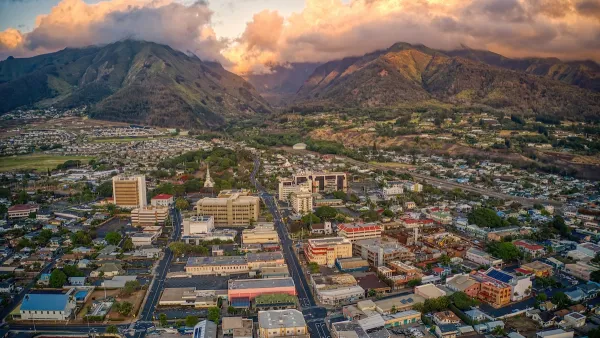

Maui's Vacation Rental Debate Turns Ugly

Verbal attacks, misinformation campaigns and fistfights plague a high-stakes debate to convert thousands of vacation rentals into long-term housing.

Planetizen Federal Action Tracker

A weekly monitor of how Trump’s orders and actions are impacting planners and planning in America.

In Urban Planning, AI Prompting Could be the New Design Thinking

Creativity has long been key to great urban design. What if we see AI as our new creative partner?

King County Supportive Housing Program Offers Hope for Unhoused Residents

The county is taking a ‘Housing First’ approach that prioritizes getting people into housing, then offering wraparound supportive services.

Researchers Use AI to Get Clearer Picture of US Housing

Analysts are using artificial intelligence to supercharge their research by allowing them to comb through data faster. Though these AI tools can be error prone, they save time and housing researchers are optimistic about the future.

Making Shared Micromobility More Inclusive

Cities and shared mobility system operators can do more to include people with disabilities in planning and operations, per a new report.

Urban Design for Planners 1: Software Tools

This six-course series explores essential urban design concepts using open source software and equips planners with the tools they need to participate fully in the urban design process.

Planning for Universal Design

Learn the tools for implementing Universal Design in planning regulations.

planning NEXT

Appalachian Highlands Housing Partners

Mpact (founded as Rail~Volution)

City of Camden Redevelopment Agency

City of Astoria

City of Portland

City of Laramie