Light rail developers in Utah are cutting costs and timelines with a new and unlikely track base: foam.

"It looks like the construction workers are stacking giant LEGO blocks, but it is actually the base of what will be a bridge for the West Valley light-rail line."

"Terry Meier, with ACH Foam Technologies, says the giant foam blocks might be lightweight, but they can hold a lot of weight. 'The density they're using on this project will withstand over a thousand pounds per square foot. So, that's a tremendous amount of weight. Much stronger than people would realize,' he said."

"Plus the lightweight fill and stabilizer saves money in project time. Dirt and other types of fill can take too long to settle. 'It takes months to get the settlement out,' said UTA Project Manager Jim Webb. 'So it helps to use Geofoam.'"

Thanks to Reconnecting America

FULL STORY: Foam blocks helping UTA save time and money

Planetizen Federal Action Tracker

A weekly monitor of how Trump’s orders and actions are impacting planners and planning in America.

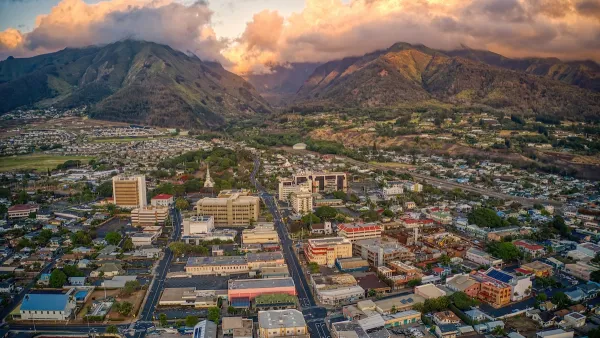

Maui's Vacation Rental Debate Turns Ugly

Verbal attacks, misinformation campaigns and fistfights plague a high-stakes debate to convert thousands of vacation rentals into long-term housing.

San Francisco Suspends Traffic Calming Amidst Record Deaths

Citing “a challenging fiscal landscape,” the city will cease the program on the heels of 42 traffic deaths, including 24 pedestrians.

Amtrak Rolls Out New Orleans to Alabama “Mardi Gras” Train

The new service will operate morning and evening departures between Mobile and New Orleans.

The Subversive Car-Free Guide to Trump's Great American Road Trip

Car-free ways to access Chicagoland’s best tourist attractions.

San Antonio and Austin are Fusing Into one Massive Megaregion

The region spanning the two central Texas cities is growing fast, posing challenges for local infrastructure and water supplies.

Urban Design for Planners 1: Software Tools

This six-course series explores essential urban design concepts using open source software and equips planners with the tools they need to participate fully in the urban design process.

Planning for Universal Design

Learn the tools for implementing Universal Design in planning regulations.

Heyer Gruel & Associates PA

JM Goldson LLC

Custer County Colorado

City of Camden Redevelopment Agency

City of Astoria

Transportation Research & Education Center (TREC) at Portland State University

Jefferson Parish Government

Camden Redevelopment Agency

City of Claremont